Custom Flange - 3d printing, CAD, Sand Casting

-

yoda69

- Posts: 1215

- Joined: Sun Mar 15, 2009 10:20 am

- cars: 2004 VYII Acclaim Wagon V6 Auto LPG/Petrol

2004 VYII Berlina sedan V6 Auto

2005 VZ Monaro CV8 manual - Location: Geelong, VIC

Re: Custom Flange - 3d printing, CAD, Sand Casting

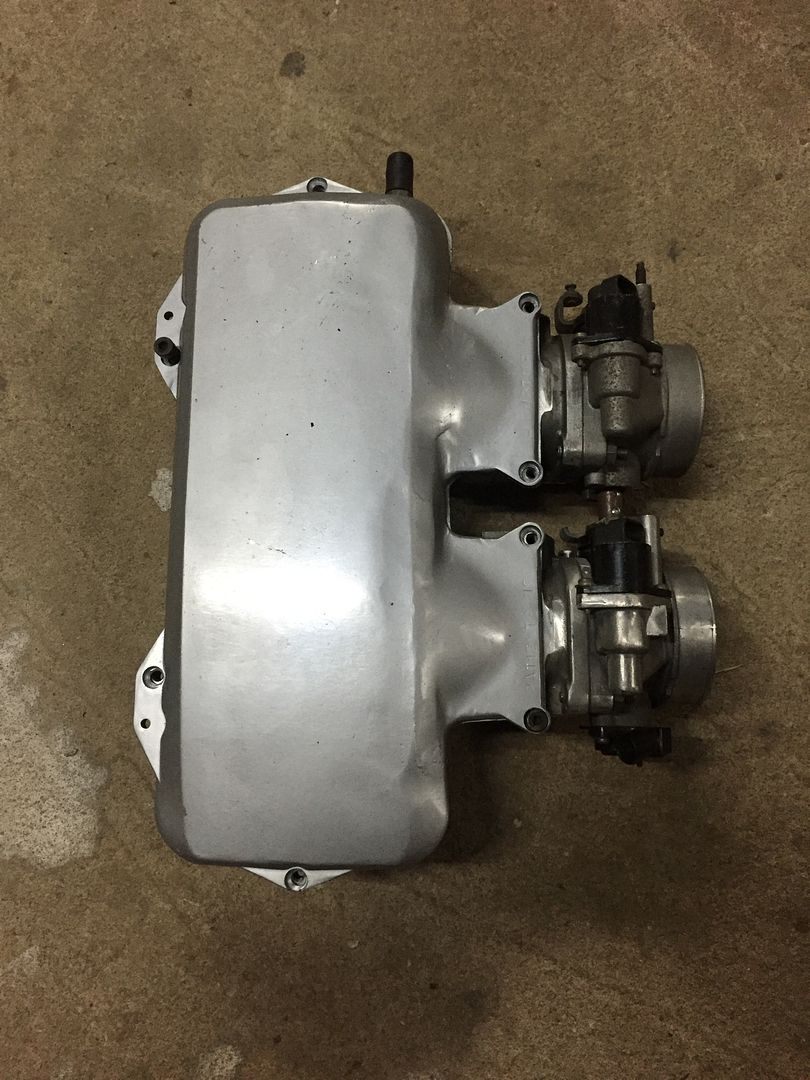

Nice looking manifold Biggvl, how'd it go on the dyno?

I was just looking at cheapest off the shelf twin throttle bodies already available, think they come in 52mm, 58mm and 65mm from what I can see. Advantage of yours is that you've basically got one lined for the front 3 cylinders and the other for the rear.

I was just looking at cheapest off the shelf twin throttle bodies already available, think they come in 52mm, 58mm and 65mm from what I can see. Advantage of yours is that you've basically got one lined for the front 3 cylinders and the other for the rear.

Re: Custom Flange - 3d printing, CAD, Sand Casting

Im sure the come one has two plates side by side just like those ones yoda pointed out...vlad01 wrote:yoda69 wrote:Could then design it to accept something like this

http://www.ebay.com/itm/BBK-GM-1992-199 ... Dk&vxp=mtr

They also do twin 65mm ones as well

nah they need to be separated with separate intake tubes to get the resonance to work correctly. That is why the come TB is good as they are separate and are designed to have a intake flange bolted to the face of the TB. Theirs was a single adapter mounted to the face of the TB so air will go nuts with turbulence. I wanted to get one of these kits and piss of their adapter and have my own made with dual ram tubes tuned to the engine within constraints of the engine bay of course.

According to chemistry, alcohol is a solution...

- vlad01

- Posts: 7794

- Joined: Mon Oct 08, 2012 6:41 pm

- cars: VP I S

VP I executive

VP II executive

VP II executive #2

VR II executive - Location: Kyneton, Vic

Re: Custom Flange - 3d printing, CAD, Sand Casting

Biggvl wrote:

when are we testing this one? and any progress on those valve springs?

I'm the director of VSH (Vlad's Spec Holden), because HSV were doing it ass about.

Re: Custom Flange - 3d printing, CAD, Sand Casting

It hasn't yet, it looks ok in the pics but needs a lot more work to make it useable, when i got it they had been using thick cork gaskets to make up for the shit machining job. The thottle linkage needs reworking also...yoda69 wrote:Nice looking manifold Biggvl, how'd it go on the dyno?

I was just looking at cheapest off the shelf twin throttle bodies already available, think they come in 52mm, 58mm and 65mm from what I can see. Advantage of yours is that you've basically got one lined for the front 3 cylinders and the other for the rear.

I might take it to work and run over it on the mill

According to chemistry, alcohol is a solution...

-

BennVenn

- Posts: 487

- Joined: Fri Mar 04, 2016 10:35 am

- cars: R33 GTST, '60 Vw Bug, Express (4G63T), GW X200

- Location: Windellama, NSW

- Contact:

Re: Custom Flange - 3d printing, CAD, Sand Casting

Isn't the tuned length measured from the valve to the mouth into the plenum? Post plenum would have no effect on resonance. Unless you are trying to make a multi resonant intake.

-

immortality

- Posts: 3424

- Joined: Thu Apr 09, 2009 12:31 pm

- cars: VH, VN, VS, VX

Re: Custom Flange - 3d printing, CAD, Sand Casting

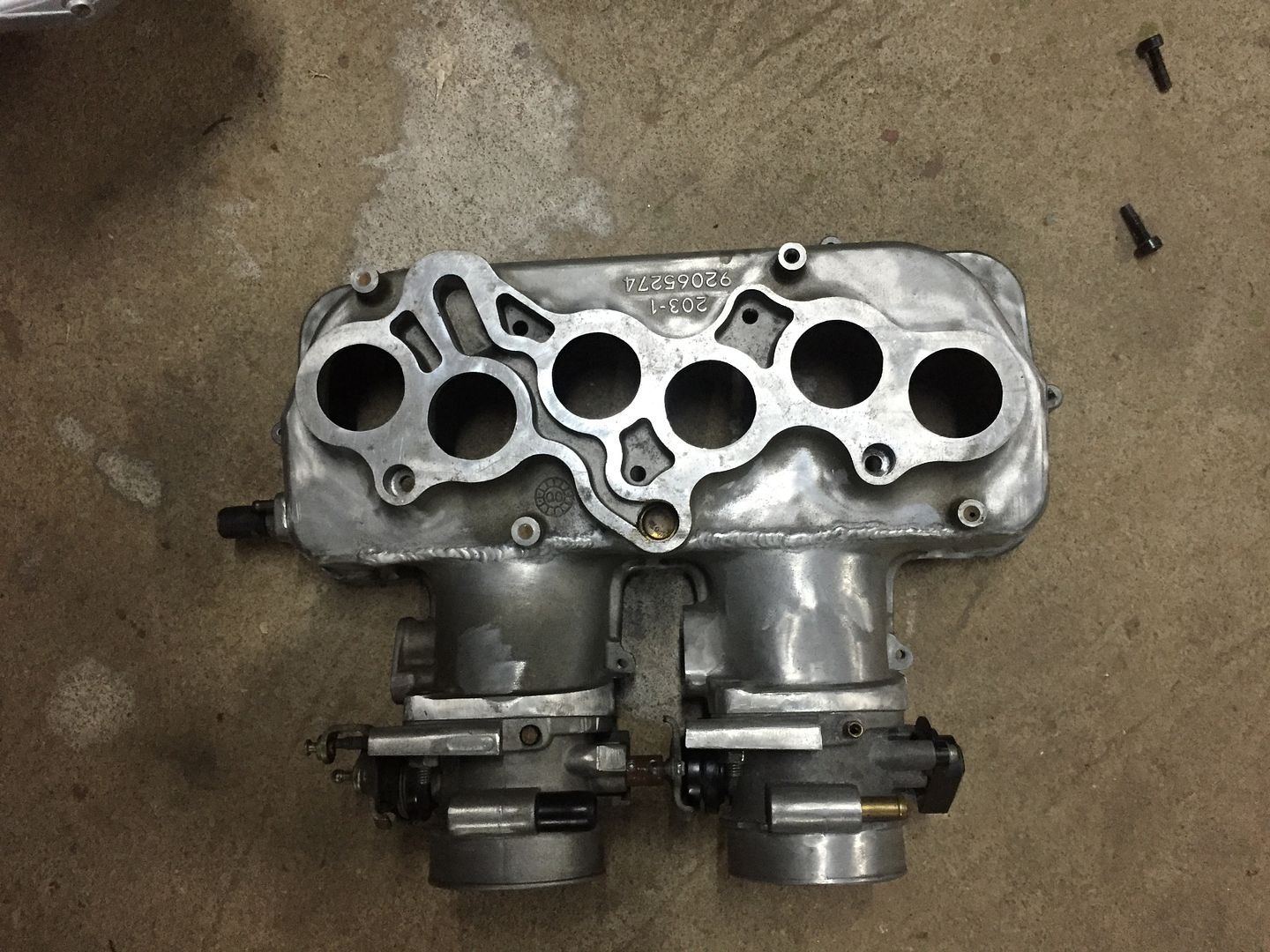

Yep, this is it (but on the V8 manifold)

- vlad01

- Posts: 7794

- Joined: Mon Oct 08, 2012 6:41 pm

- cars: VP I S

VP I executive

VP II executive

VP II executive #2

VR II executive - Location: Kyneton, Vic

Re: Custom Flange - 3d printing, CAD, Sand Casting

absolutely not, from our own dyno testing we found the ram tubes before the plenum have more of an effect that the runners themselves.BennVenn wrote:Isn't the tuned length measured from the valve to the mouth into the plenum? Post plenum would have no effect on resonance. Unless you are trying to make a multi resonant intake.

They are actually linked to the runner length but overall have the biggest effect.

I'm the director of VSH (Vlad's Spec Holden), because HSV were doing it ass about.

-

BennVenn

- Posts: 487

- Joined: Fri Mar 04, 2016 10:35 am

- cars: R33 GTST, '60 Vw Bug, Express (4G63T), GW X200

- Location: Windellama, NSW

- Contact:

Re: Custom Flange - 3d printing, CAD, Sand Casting

Maybe the effect you are seeing is plenum volume / charge velocity / laminar flow?

Resonant 2-stroke exhaust design really only concerns the expansion chamber not so much the muffler down stream. I would have thought intake is no different.

Then again, my old telstar had a resonant intake tract before the TB...

Resonant 2-stroke exhaust design really only concerns the expansion chamber not so much the muffler down stream. I would have thought intake is no different.

Then again, my old telstar had a resonant intake tract before the TB...

- vlad01

- Posts: 7794

- Joined: Mon Oct 08, 2012 6:41 pm

- cars: VP I S

VP I executive

VP II executive

VP II executive #2

VR II executive - Location: Kyneton, Vic

Re: Custom Flange - 3d printing, CAD, Sand Casting

BennVenn wrote:Maybe the effect you are seeing is plenum volume / charge velocity / laminar flow?

Resonant 2-stroke exhaust design really only concerns the expansion chamber not so much the muffler down stream. I would have thought intake is no different.

Then again, my old telstar had a resonant intake tract before the TB...

The pre plenum intake tube is part of the engine intake resonance and I too thought it would be lest importance until we accidentally tested it by running straight TB with no intake and lost about 15Nm over the entire rpm range with less restrictive intake lol. So more testing and we found certain lengths produced best power. But those said lengths seem to depend on the initial runner length which in turn depend on the cam and general engine config.

I'm the director of VSH (Vlad's Spec Holden), because HSV were doing it ass about.

-

BennVenn

- Posts: 487

- Joined: Fri Mar 04, 2016 10:35 am

- cars: R33 GTST, '60 Vw Bug, Express (4G63T), GW X200

- Location: Windellama, NSW

- Contact:

Re: Custom Flange - 3d printing, CAD, Sand Casting

A straight TB open to air would have huge turbulence. Did you try a bellmouth?

My primary job is electronics and part of the training (over a decade ago...) was waveguide RF propagation. It's very similar to tuned manifolds and the 'termination' needs to be impedance matched. We have electrically comparable components to bellmouths, plenums, runners, cross flow ports etc...

The proof is in the torque curve as you say. I've always had an interest in tuned intakes since seeing a vk intake.

I wonder how much work a flow bench would be...

My primary job is electronics and part of the training (over a decade ago...) was waveguide RF propagation. It's very similar to tuned manifolds and the 'termination' needs to be impedance matched. We have electrically comparable components to bellmouths, plenums, runners, cross flow ports etc...

The proof is in the torque curve as you say. I've always had an interest in tuned intakes since seeing a vk intake.

I wonder how much work a flow bench would be...