DavoF wrote:The 5/50 and 15/15 seem to have similar results for wear. For the 5/50 oxidation/nitration etc it looks like they have used the wrong comparison definition file to me cause if those figures are correct then the oil would be a sludgy black mess. The tan/tbn is "0" (not reported or tested) for the 15/50 so hard to compare those values.

Overall it seems the 5/50 and 15/50 are performing in a similar way which is to be expected i guess as they are both 50 weight.

Another thing about the wear metals, if you know what metals your crank/bearings/ cam etc are made of it makes it a lot easier to know what is wearing. Copper and lead are most likely bearings. I had an old XE falcon for a few years (hated it lol) and when I tested its oil I found copper and lead of around 30ppm each time. So I think your wear levels are pretty good. Hard to tell unless you have typical wear data as different types of engines will wear at different rates.

The1's Daily

Re: The1's Daily

Below is my tests, then DavoF's reply.

- vlad01

- Posts: 8124

- Joined: Mon Oct 08, 2012 6:41 pm

- cars: VP I S

VP I executive

VP II executive

VP II executive #2

VR II executive - Location: Kyneton, Vic

Re: The1's Daily

looking at those, doesn't seem that bad. one shows silicon elevated, likely dust i would say got in past the filter.

the copper is a little concerning considering lead is low, so looks like some bearing has worn through the babbitt. commonly cam bearings go first on the ecotec and common for them to spin.

the copper is a little concerning considering lead is low, so looks like some bearing has worn through the babbitt. commonly cam bearings go first on the ecotec and common for them to spin.

I'm the director of VSH (Vlad's Spec Holden), because HSV were doing it ass about.

Re: The1's Daily

i guess need to see another car's oil sample to see if it's normal or not, but either way 300k with a WOT to and from work each day. Be interesting anyhow to see how the results come out from this other place. I see you ordered your kit.

- vlad01

- Posts: 8124

- Joined: Mon Oct 08, 2012 6:41 pm

- cars: VP I S

VP I executive

VP II executive

VP II executive #2

VR II executive - Location: Kyneton, Vic

Re: The1's Daily

yep, I am curious to see the damage on mine, WOT from start up quite a lot of the time

timing chain sounds stretched by the way the lifters rattle at a certain rpm. Still going great though.

its what happens when you have a T5 right?

I see the PO of the car this T5 came from had fun.

I wonder what the oil test would show on this one?

timing chain sounds stretched by the way the lifters rattle at a certain rpm. Still going great though.

its what happens when you have a T5 right?

I see the PO of the car this T5 came from had fun.

I wonder what the oil test would show on this one?

I'm the director of VSH (Vlad's Spec Holden), because HSV were doing it ass about.

-

yoda69

- Posts: 1226

- Joined: Sun Mar 15, 2009 10:20 am

- cars: 2004 VYII Acclaim Wagon V6 Auto LPG/Petrol

2004 VYII Berlina sedan V6 Auto

2005 VZ Monaro CV8 manual - Location: Geelong, VIC

Re: The1's Daily

I think some of those metal samples may be a bit hard to fit in the jar.

Re: The1's Daily

V8 Supercar oil test eat your heart out.

Yeh no amazingly i have no rattle at all, not even lifter noise, only for a split second on cold start somedays but nothing while hot. The oil pressure always comes up instantly, the stock oil pressure sensor dash light comes on at <9psi i think in the factory manual and it never blinks or stays on at startup.

Even though i WOT mine id like to say it's not flogging it, dont do burnouts and dont hold it at redline, just good full throttle runs only when hot.

Yeh no amazingly i have no rattle at all, not even lifter noise, only for a split second on cold start somedays but nothing while hot. The oil pressure always comes up instantly, the stock oil pressure sensor dash light comes on at <9psi i think in the factory manual and it never blinks or stays on at startup.

Even though i WOT mine id like to say it's not flogging it, dont do burnouts and dont hold it at redline, just good full throttle runs only when hot.

- vlad01

- Posts: 8124

- Joined: Mon Oct 08, 2012 6:41 pm

- cars: VP I S

VP I executive

VP II executive

VP II executive #2

VR II executive - Location: Kyneton, Vic

Re: The1's Daily

yeah no burnout for me, I don't see the point of it. I take it close to red line on occasions but only when hot.

but I found the ecotec are a far more robust engine is terms of ware and noise. the pre ecotec tend to start making noises around the 150-200k mark and upto 250k for a babied one. once 300k they rattle all right but they will still go well past that and live a long but noise life.

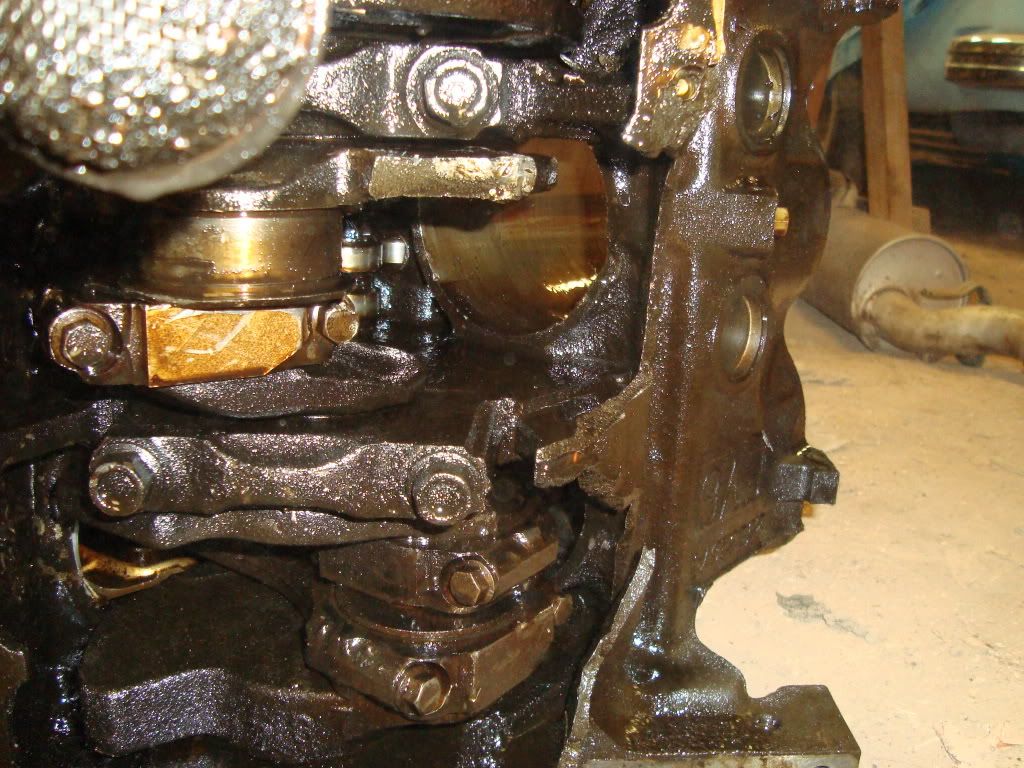

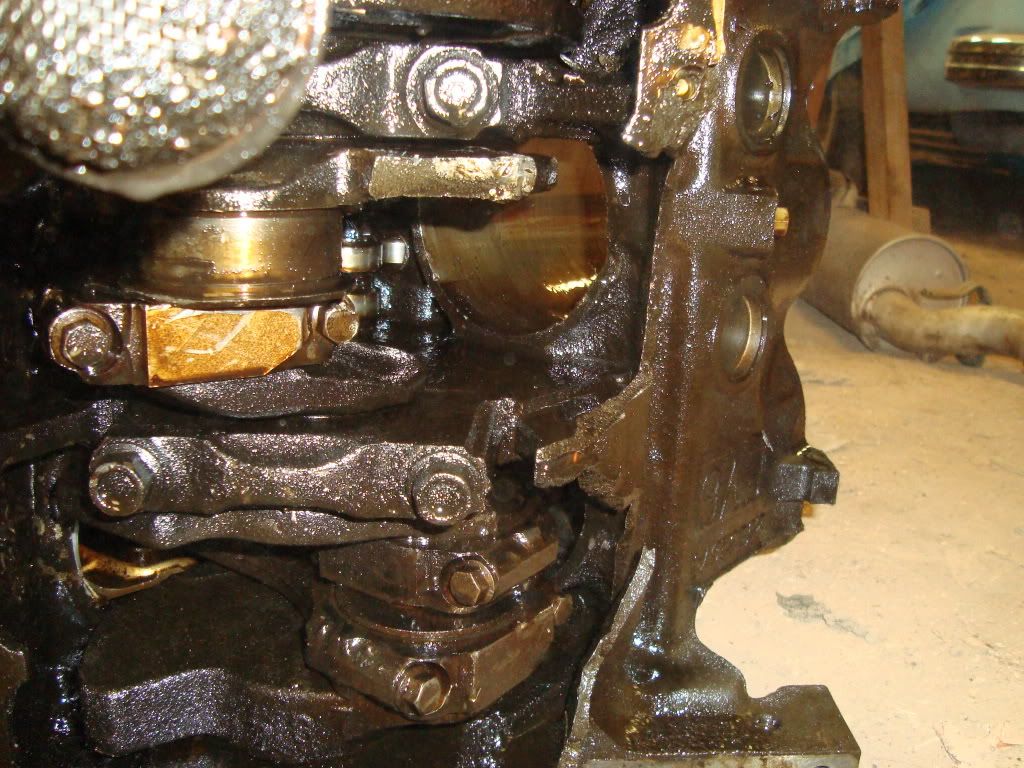

my mates VY which is now the block I am going to use, its fantastic for a thrashed 350k engine, hone marks are still more of less there, no ridges on the bore what so ever. spotless inside, cam and lifter are pretty good for 350k

No corrosion anywhere due to regular coolant changes. The only noise it has was the evidence the valve spring was about to break and then it did. The only major wear I could see was the mace 1.9 rockers were staring to eat them selves up where the push rods pivots on them.

I think its because the ecotec is far more refined engine and don't suffer as much vibration and harmonics that tend to eat the pre ecotec up when reved too much.

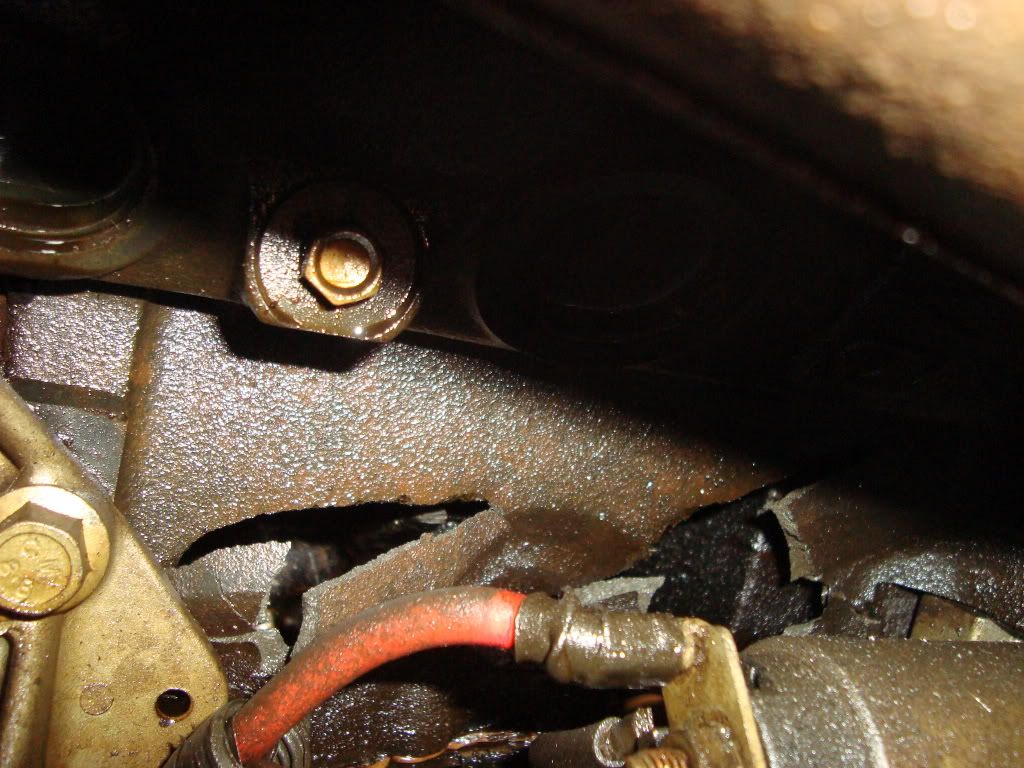

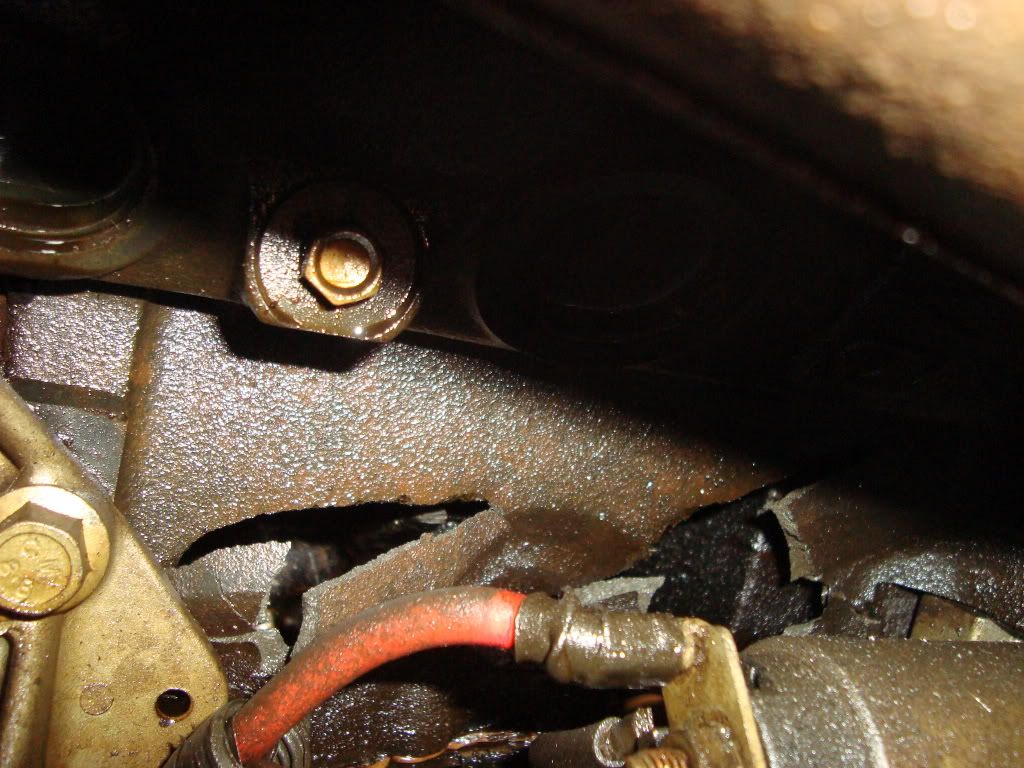

One thing that kills ecotecs is this.

but I found the ecotec are a far more robust engine is terms of ware and noise. the pre ecotec tend to start making noises around the 150-200k mark and upto 250k for a babied one. once 300k they rattle all right but they will still go well past that and live a long but noise life.

my mates VY which is now the block I am going to use, its fantastic for a thrashed 350k engine, hone marks are still more of less there, no ridges on the bore what so ever. spotless inside, cam and lifter are pretty good for 350k

No corrosion anywhere due to regular coolant changes. The only noise it has was the evidence the valve spring was about to break and then it did. The only major wear I could see was the mace 1.9 rockers were staring to eat them selves up where the push rods pivots on them.

I think its because the ecotec is far more refined engine and don't suffer as much vibration and harmonics that tend to eat the pre ecotec up when reved too much.

One thing that kills ecotecs is this.

I'm the director of VSH (Vlad's Spec Holden), because HSV were doing it ass about.

Re: The1's Daily

no doubt mace rockers or any reworked rocker isn't good for the valvetrain. Just the heat from reworking them would have to put them out? Then people go running then on stock springs

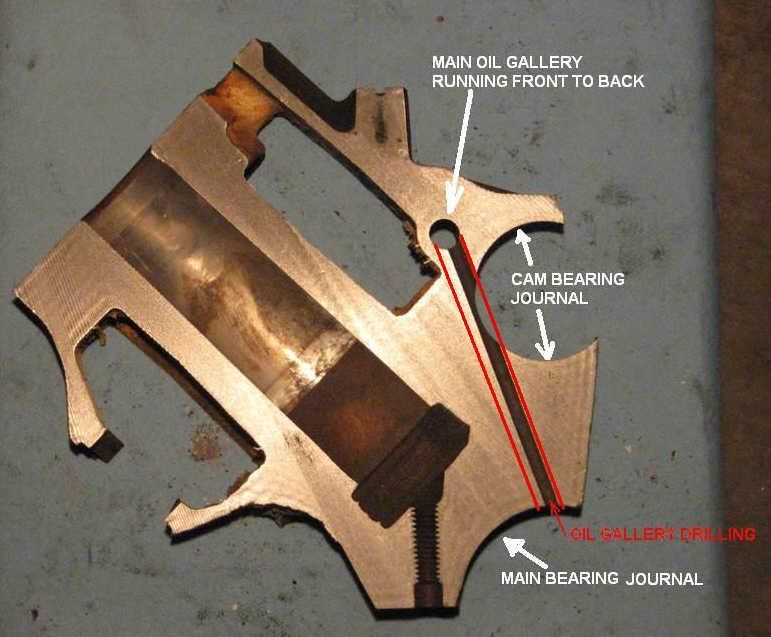

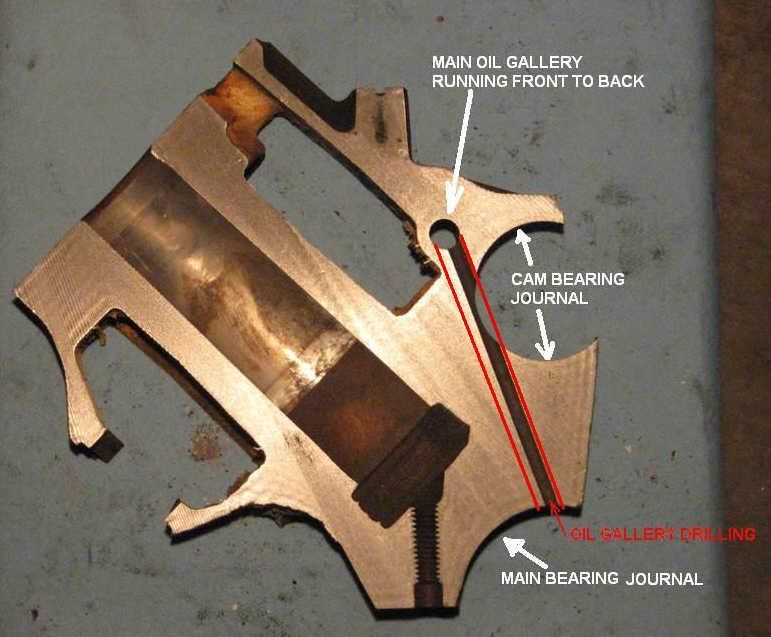

Im far from a mechanic but is the oil gallery there what people get machined bigger to help stop this issue?

Im far from a mechanic but is the oil gallery there what people get machined bigger to help stop this issue?

- Holden202T

- Posts: 10394

- Joined: Sat Feb 28, 2009 9:05 pm

- Location: Tenambit, NSW

- Contact:

Re: The1's Daily

I'd say so, the cam bearings are basically restricting the oil to the main caps and that would then feed the big ends so you can see how it can cause issues on a high rpm motor

No matter what the question is, the answer is always more horsepower!

Just starting out? Have a read of the getting started guide

Basic tuning of a delco ECM with $12P thread

Advanced tuning of a delco ECM with $12P thread

Just starting out? Have a read of the getting started guide

Basic tuning of a delco ECM with $12P thread

Advanced tuning of a delco ECM with $12P thread

- vlad01

- Posts: 8124

- Joined: Mon Oct 08, 2012 6:41 pm

- cars: VP I S

VP I executive

VP II executive

VP II executive #2

VR II executive - Location: Kyneton, Vic

Re: The1's Daily

yes,The1 wrote:no doubt mace rockers or any reworked rocker isn't good for the valvetrain. Just the heat from reworking them would have to put them out? Then people go running then on stock springs

Im far from a mechanic but is the oil gallery there what people get machined bigger to help stop this issue?

this pic is from a ecotec/L67 specialist engine builder. He says the core of the casting varies from engine to engine up to 6mm, so some of the engines have the gallery in the wrong place due to the core of the casting not being in the right place. So basically its the internal parts of the casting is out relevant to the out side of the cast also being out reliant to the oil passage drilling. nice work GM!

also regarding the rockers, I put it down to the metallurgical effects of what appears to be welded rockers, remachined and redrilled pushrod location.

my question is how is that suppose to work long term? the metal looks too soft and just squished in by the push rod load. push rods were fine, the rockers were the ones which were eating up.

I'll just go with the cam and ported heads on mine thank you very much. rockers are a waste of time and money imho.

also I noticed the push rods were rubbing on the head gaskets because of the rockers.

I'm the director of VSH (Vlad's Spec Holden), because HSV were doing it ass about.