So I got to work yesterday.

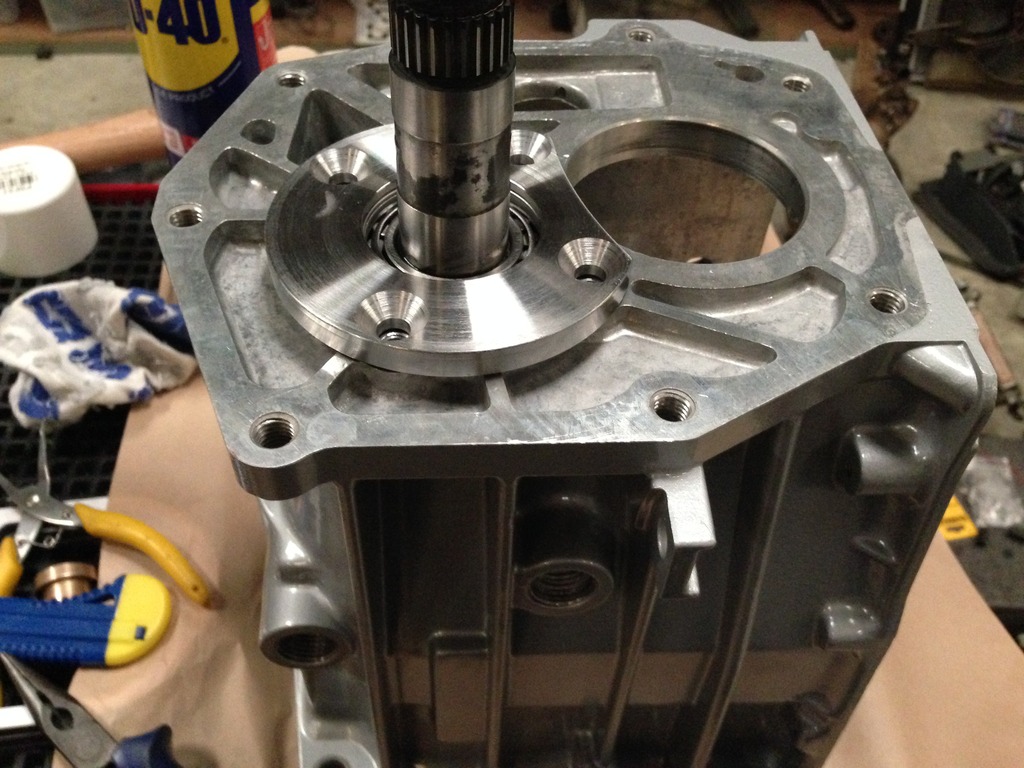

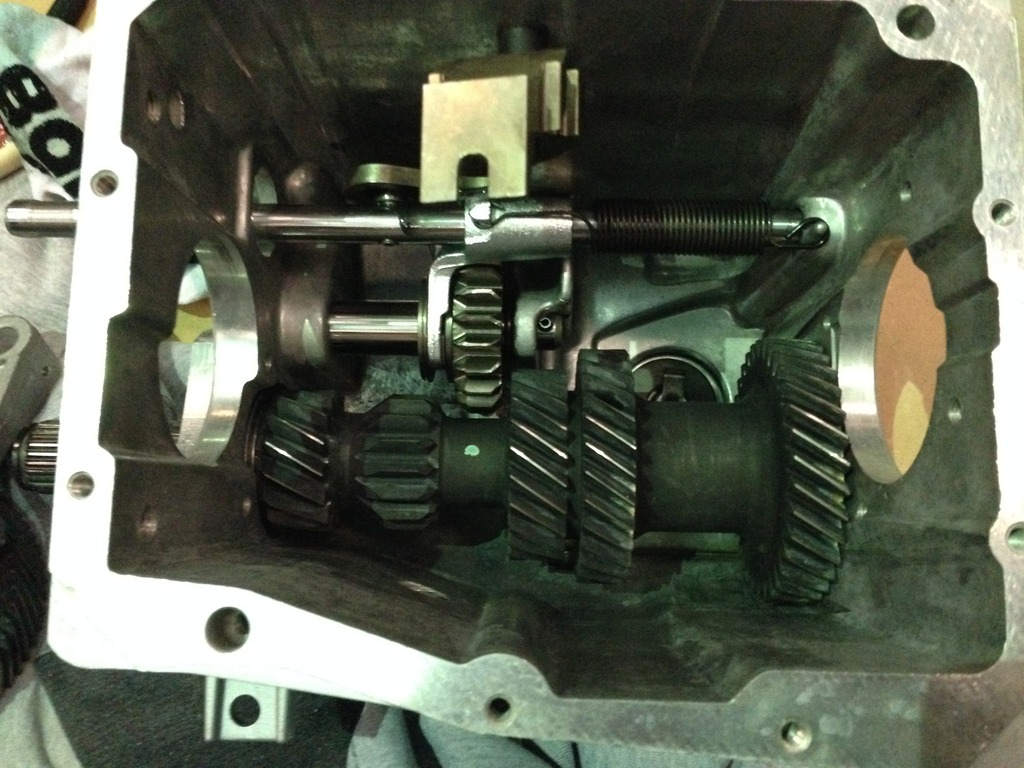

Installed reverse idler shaft and gear and then installed the counter. Once that was done I pressed on the bearing as that must be done while inside the case otherwise you can't get it in there.

- IMG_0870_zpskp0mrvjn.jpg (187.58 KiB) Viewed 3043 times

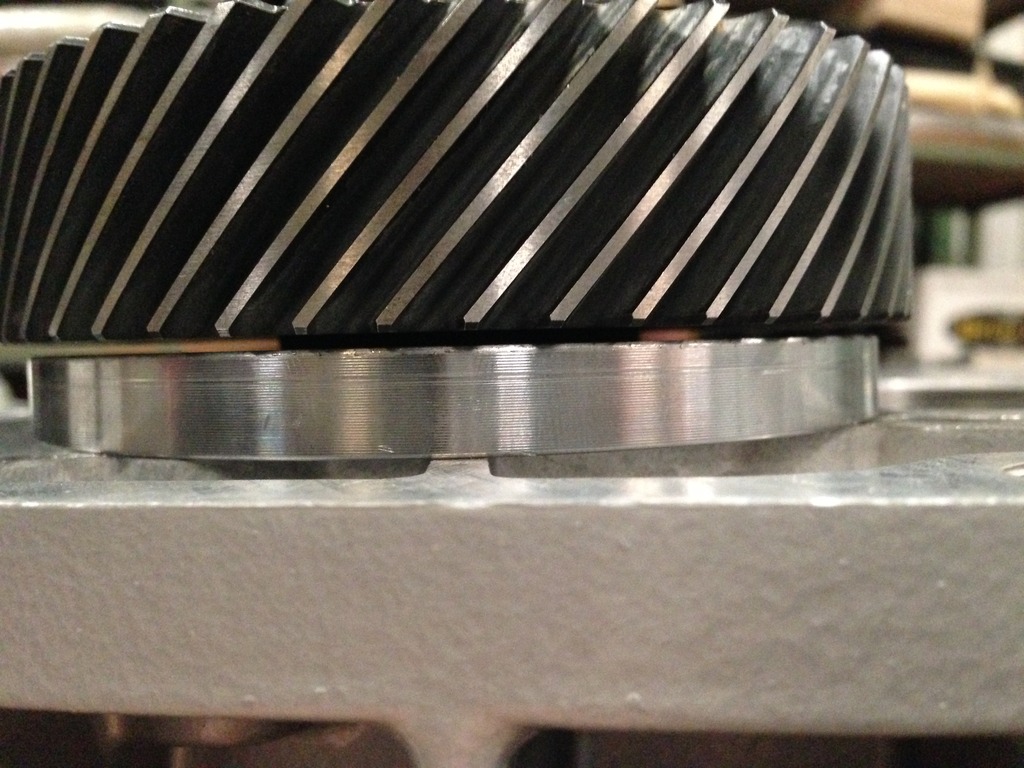

Next was to set up the preload with a service and peelable shim.

- IMG_0871_zpstt4lmr2c.jpg (225.34 KiB) Viewed 3043 times

You peel them with a razor blade, they are ultra thin and looks like its just a solid shim. Be careful they cut you super easy.

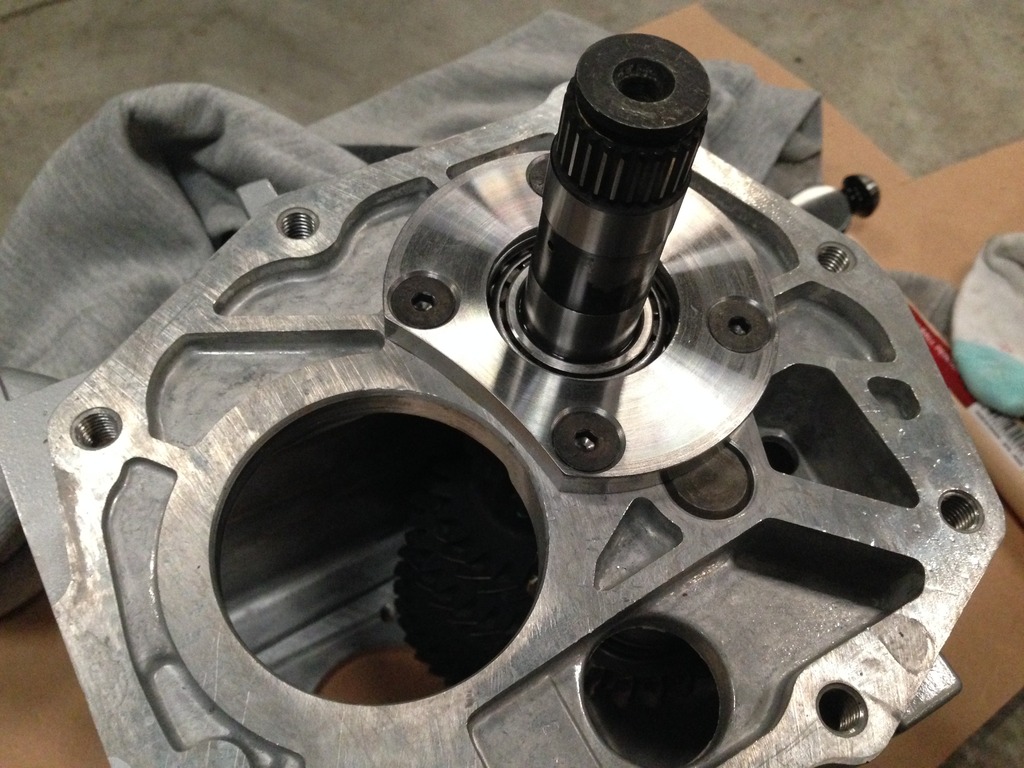

- IMG_0872_zpsyhxf3mtd.jpg (188.41 KiB) Viewed 3043 times

80% of the shim gone latter.....

- IMG_0880_zpsx00yhinp.jpg (218.87 KiB) Viewed 3043 times

checking preload along the way with my creative adapter. 1/4" drive did not fit in this hole like most people reckon so I have to doing it this way but worked a treat.

- IMG_0873_zpss3e9qrg3.jpg (227.72 KiB) Viewed 3043 times

Getting very close with one peel away I had about 7 in-lb and the next one got me just over 2 with dry install and fraction over 2 in-lb one finally assembled. Range is 2-4 so its pretty good.

- IMG_0876_zps23mwgzsw.jpg (183.93 KiB) Viewed 3043 times

5th gear clearance is great on this setup, more than most people get with these plates. it really depends on individual gearboxes.

- IMG_0877_zps8ealdy3h.jpg (224.33 KiB) Viewed 3043 times

So that was that sorted!

- IMG_0878_zpsisuqxpcl.jpg (229.29 KiB) Viewed 3043 times

- IMG_0879_zpsrsgfqvq4.jpg (244.62 KiB) Viewed 3043 times

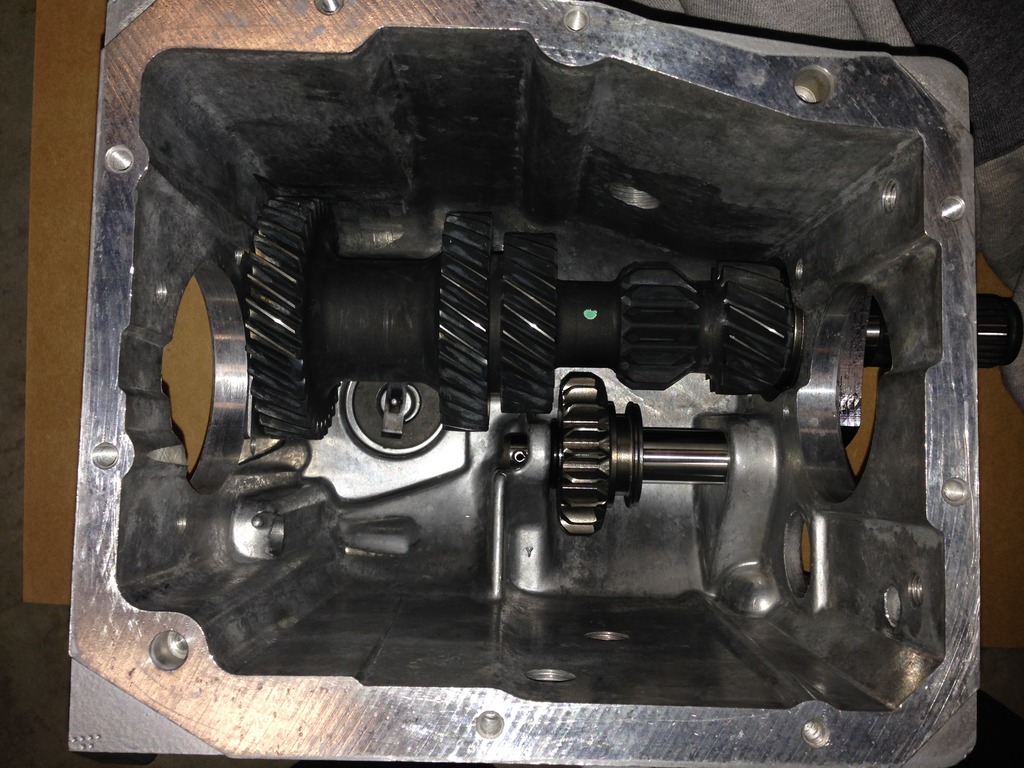

Next was the reverse and 5th shift mechanisms.

- IMG_0881_zpsarac2qxc.jpg (219.5 KiB) Viewed 3043 times

After I prep'd the input shaft, 4th synco ring, bearings, washers and shims. Installed the main shaft.

Put the whole box in a spare bellhousing so I could work on the rear main bearing and 5th gear system.

- IMG_0882_zpsrfdkqjkm.jpg (202.67 KiB) Viewed 3043 times

5th gear stuff sorted and checking operation.

- IMG_0883_zpsxzdfhpoa.jpg (227.96 KiB) Viewed 3043 times

And finally the speedo drive gear.

- IMG_0885_zps9x93ar57.jpg (249.89 KiB) Viewed 3043 times

Next on the list is to sort out the cover and 1-2, 3-4 shift mechanisms which I have no idea as none of my manuals show which way around the parts go which clearly they have a certain way when I look at them. I have a spare t5 I bought a few weeks ago which I needed one shift component from the cover anyway, so I will study that to work it out.

The other part I now need is the tail shaft bushes, once those 2 things are done I can finally seal the extension housing on and then proceed to shimming the front input end to get a 0 end float.

Only other thing is a shifter, going to go for the billet products T5 shifter. Exy but looks the best made out of all the others on the market.

I'm the director of VSH (Vlad's Spec Holden), because HSV were doing it ass about.