I had deburred the oil pump gallery inlet and did minor clean-up of the valley before I sent it off for machining.

The metal is pretty soft and cleans up really easily. I didn’t go too crazy, just took off the casting dags. You see some go to the trouble of polishing the valley, but I am not sure this is beneficial as it reduces the surface area for heat transfer.

- Valley.JPG (132.21 KiB) Viewed 11081 times

I’m not against the rear seal conversions but I am just running the factory rope rear seal.

I think if you keep your oil changes up, and keep the PCV system in place with a vacuum in the sump, there’s no reason why a rope seal shouldn’t last (if you keep the revs down as well). Let them breath to atmosphere (or through catch can then to atmosphere) there has to be a positive sump pressure which is asking for trouble. If the PCV is working there should be 0.5” H20 vacuum in the sump (at idle) which solves a lot of issues. Having said that, this one was leaking - but the rear main in my one tonner is still ok with well over 300000kms on the motor.

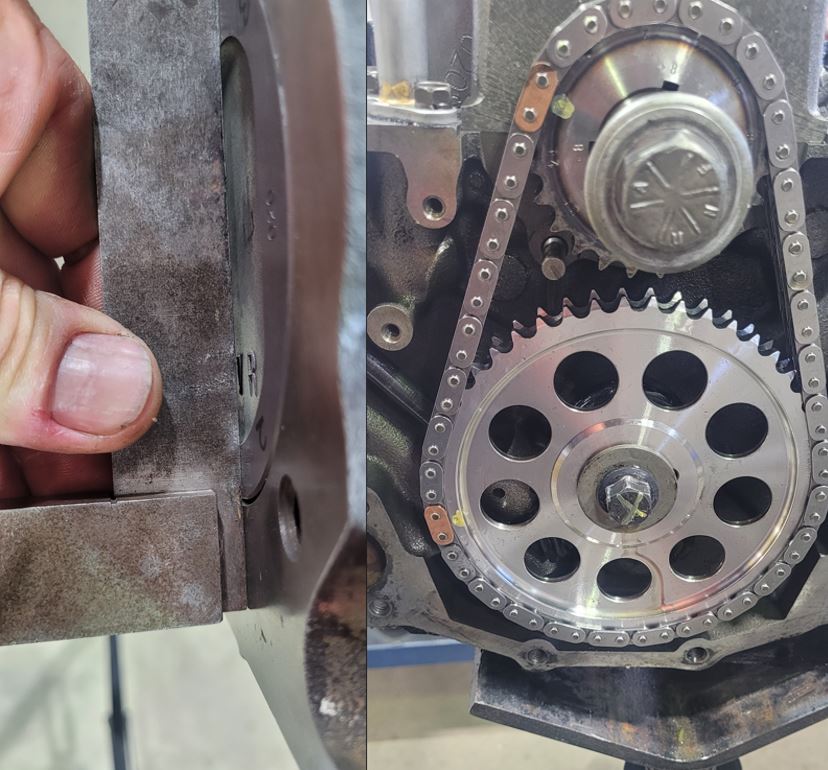

I didn’t plan on doing any oiling mods other than just a spot of weld over the cam bolt oiler, and redrilling it so it now faces the gears. The other chain oiler is still in place.

And these are the Crower Cam Saver lifters.

There is just a flat that is about 0.002” deep milled on the side of the lifter. The intent would look to be that it is a small path for oil to leak through, and even though the lifter rotates, some of that leaked oil would fall onto the cam lobe.

Could well be a gimmick, but regardless Crower are a reputable lifter brand, so you’d have some confidence in the materials/manufacture regardless of how effective the cam saver function is.

- Cam and Lifters.JPG (92.99 KiB) Viewed 11081 times

And my calcs are wrong – either that or the deck height is less than I thought or the piston comp height is actually 1.507” which is unlikely.

Pistons are 0.002” proud of the deck, albeit crudely measured with a dial gauge. So could have 9.6:1 compression if I’m lucky. Possibly getting a bit high for what this engine is and might need to be careful with what petrol goes into the tank but if I get it right it should be quite healthy.

But considering minimal decking, these pistons seem to be a pretty good choice for a mild engine.

Cam degreed in Ok. Took a guess straight up of 2 degrees advanced and it matched the card.

- Piston to Deck Height.JPG (108.56 KiB) Viewed 11081 times

For the engine assembly lube, I used the CRC Engine Assembly Sta-Lube. No idea how good or bad it is, but I’ve never had an issue with it. For me the big advantage over oil is that for an engine like this that will more than likely not be started for a few months, you have some confidence that the assembly lube will still on the bearings when I get around to firing it up.

For the cam chain and similar parts, I just put them in a clip seal bag, add a bit of oil and allow to soak overnight.

For the cam lobes, I just use what came with the cam. Same with the conrod bolts. All the other bolts just get engine oil on the threads and under the heads.

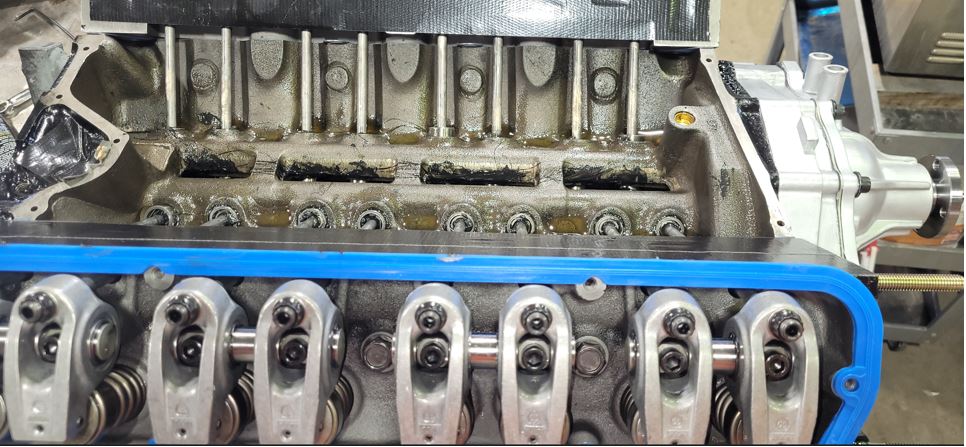

Heads are on and torqued up. I am always hawky of the middle bolts as they never feel quite right to me. I just settle for the lower end of the torque spec and leave it at that.

Rockers are just the Street Terra adjustable.

Shame the rocker cover gaskets aren’t a plain black colour so they don’t stand out as much as what they do.

- Assembled.JPG (107.51 KiB) Viewed 11081 times

But engine is more or less assembled now.

I still need to fit the intake manifold but I want to get the gasket faces machined. I stuffed up badly when trying to match the ports and kissed the gasket face with the bur, so a light skim will fix that up. I also have no idea how much came off the heads so figure 0.005” skim should also go someway to getting the bolts closer to the centre of the hole. At the moment, the manifold will fit fine as it is, but the bolts are closer towards the inner edge of the bolt hole and a light skim will help centre it up.

I still have to prime the oil system, and have ordered a new RAE distributor and a set of ignition leads as the old set had a couple of burnt ones. Also a ordered a new starter motor and a 120 amp VS style alternator – so will need to mod the mounting bracket for that too.

Other than that, that’s pretty much it until I get the rest of the car back and can start putting it back together.

I’ll be sure to put the engine covers on backwards too.