Well its been a while and ALOT has happened!

so after i built the new motor, i put it on the dyno to confirm oil pressure and sadly it still had the same issue, i had more pressure but it still dropped off at high revs.

we played around with different oil pumps and shims in the pressure side etc and ended up adding some more oil which was enough to get a mostly full pull, and a horepower PB!

disregard the RPM along the bottom, its about 1200-1500rpm higher than actual.

So with the issue still there i decided to pull the engine, and look at the pickup, it seemed to make sense as the restriction at higher revs causing caviation and loss of pressure... it was also a good opportunity to pull the rod caps and confirm i hadnt damaged the bearings!

So this is the pickup i had in it .... the filter part of it is probably a bit of a restriction, but even if its not the diamater of the tube probably is!

As you can see the new pickup tube is a fair bit larger, and this tube matches the AN fitting ID as well as the braided hose ID.

I also got a filter which is much more flowy than the old one!

Now i had the pickup worked out it was time to sort out the sump itself. First thing i measured when i took the sump off was how far down the dipstick went from the block pan rail, and then also how fair down the stud girdle was, as its the lowest point in the engine.... turns out that with the stock sump at the full level it probably had a maximum of 2ltrs of oil in it .... this obviously wouldnt have been helping .... on top of that i could fill it another 1 inch before it would get to the stud girdle.

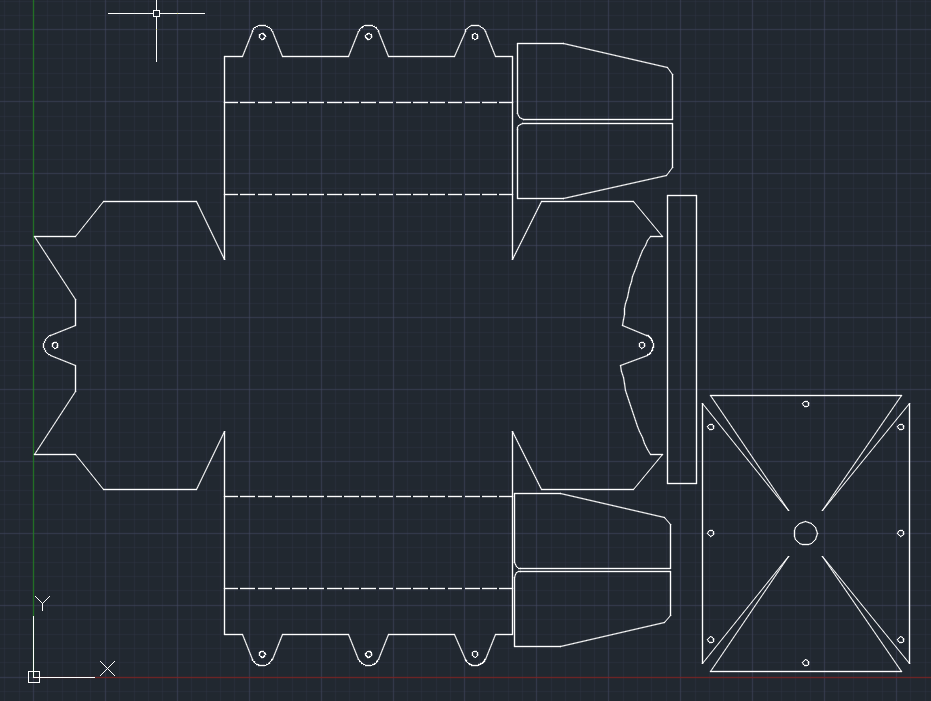

So i took a heap of measurements and drew up a cad design, and then printed it and transferred to cardboard ... happy with that!

- 4.jpg (120.84 KiB) Viewed 1984 times

So once i was happy with the cad file i added a few pieces for baffles and oil diverters etc and then got the whole lot lazer cut.

- 5.png (63.57 KiB) Viewed 1984 times

I then hacked the bottom off my original sump.

and started bending and welding up the ikea flat pack kit!

Then glued it onto the sump!

Then added some plates to try and keep as much oil at the pickup as possible on a launch.

Then put a baffle over the top of it. (only thing not in this picture is the cut out for the dipstick).

Welded the AN fitting on the outside and we're good to go!

So instantly when i started the engine with this new sump / pickup i had stupid amounts of oil pressure, went over 100psi at idle ..... i had to remove the washers i had under the spring and also wind out the adjuster screw and that was still a bit too high.

I ended up machining the end of the bolt that holds the spring in to get a few more MM from it and with 15w/40 oil it was just ok once up to temperature.

so i was fairly confident that i had just removed a massive restriction so it was time to go back to the dyno - results speak for themself!

so on top of having good oil pressure, i also fixed a failed second fuel pump and was able to get a new PB of 445HP and a full power run in ....... well almost!

http://www.youtube.com/watch?v=1LoX_65z8BY

So that ended the day as i didnt want try anything else, and at the time thought i probably just blew a head gasket (or worse)

I did a compression test when i got home and got 128-130psi on all cylinders, the water looked clean and so did the oil so i was not sure what was going on .... it also ran perfectly fine other than being a bit low on oil

the more people i talk to the more people tell me this is fairly common at high revs to fill the tappet cover with oil and then in my case it just blew out the catch can filter!

so the current plan is to remove the HV oil pump and go back to a stock one and port it out, and then also see if i can get some pushrods to restrict oil flow to the top of the motor!

so its been an interesting journey but mostly good progress and results!