Page 1 of 10

Custom Flange - 3d printing, CAD, Sand Casting

Posted: Fri Mar 25, 2016 10:07 am

by BennVenn

Mentioned in Tazzi's 3d printing thread, I need a few manifolds made up for my superchared VW project. This is how I do it. This one is simple, its an adaptor plate to bolt a GB TBI to an AMR500 Charger. No Cores, just a simple two part mold.

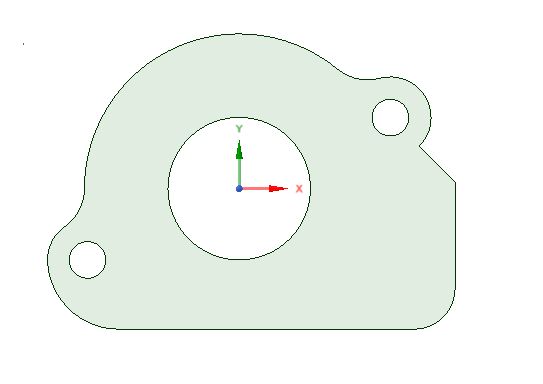

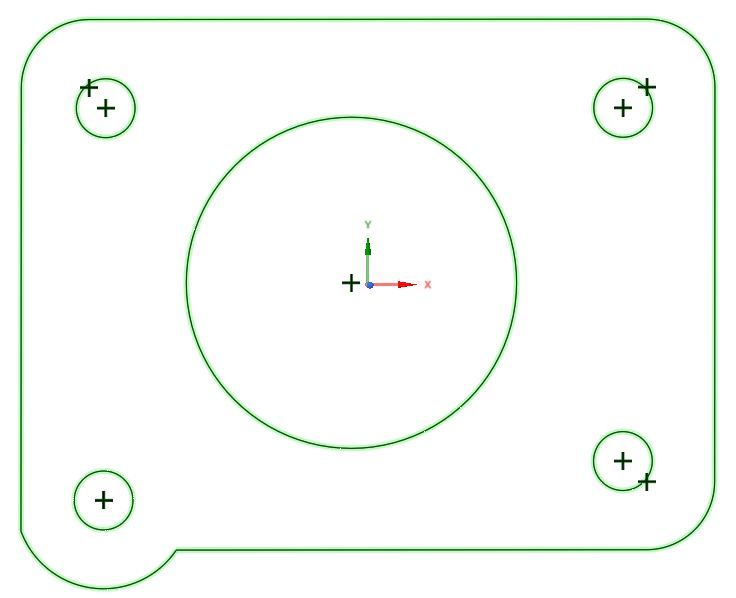

We start by drawing up both flanges in CAD.

- TBI Flange.JPG (19.38 KiB) Viewed 8041 times

- AMR Flange.JPG (33.98 KiB) Viewed 8041 times

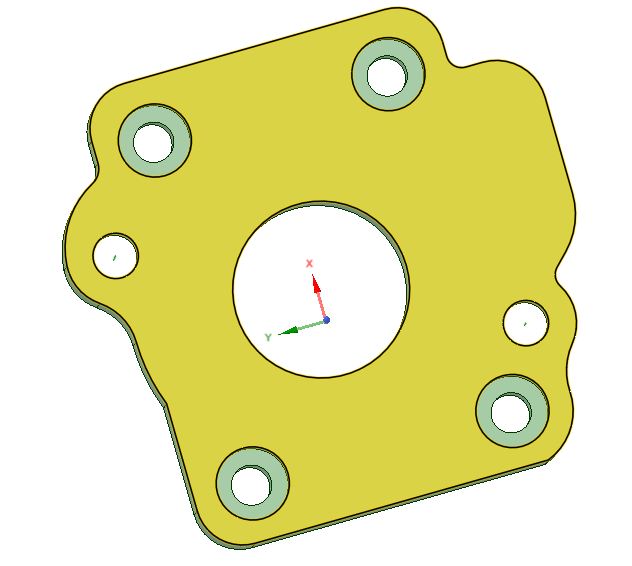

Then we merge them so no support bolts are interfering, no breach of any sealed surfaces, add clearance for both the bolt head and the socket to tighten them. Add a mm either side for finishing on the mill/lathe and we're almost ready.

- TBI_Flange merge.JPG (37.74 KiB) Viewed 8041 times

We print a 1mm slice to confirm everything is lined up and no gross errors.

Now I fill in the through holes and add a dimple to locate the drill when drilling. I do this because every edge must have a draft angle to help removal from the sand. It is just easier not to have complete small diameter through holes and instead drill them in the finishing stage.

I'm printing the master pattern now, Should be done in an hour or so. I'll add more photo's when I'm ready to make the sand molds and pour them.

Happy Easter Holidays!

Re: Custom Flange - 3d printing, CAD, Sand Casting

Posted: Fri Mar 25, 2016 10:14 am

by yoda69

Nice work, I'm very interested to see how this progresses and the final product.

Re: Custom Flange - 3d printing, CAD, Sand Casting

Posted: Fri Mar 25, 2016 10:29 am

by Gareth

Wow

im watching with great interest

Re: Custom Flange - 3d printing, CAD, Sand Casting

Posted: Fri Mar 25, 2016 11:50 am

by HQ355

Me 3

Re: Custom Flange - 3d printing, CAD, Sand Casting

Posted: Fri Mar 25, 2016 12:20 pm

by immortality

+4 Life is easy when you have access to the right equipment

Re: Custom Flange - 3d printing, CAD, Sand Casting

Posted: Fri Mar 25, 2016 4:12 pm

by BennVenn

OK, so a bit of a backstory:

I usually cast with what is known as 'greensand'. This is clay bonded sand with water to help bind it all together. There are limits to the detail and surface finish you can achieve with greensand due to the required porisity of the sand to aid in venting when the 900deg metal gets poured into the mold. This means course grain sand and due to the water to bind it, it evaporates and requires constant mulling (compacting and breaking). It is hard work! but it works well.

I invested the money and got 15kgs of 'Petrobond' binder (~$220 in shipping alone from the US!!!). This works in the same way as greensand but uses synthetic 2-stroke oil to bind. No evaporation, no constant mulling. No water means no steam which means extremely fine grade sand (I'm using al-ox 120grit sand blasting media) and almost mirror surface finish. You can easily cast the detail off a 10c piece. I can even see my fingerprints in the casting! Being my first time mixing this oil bonded sand I ran into a few issues. I'm still working out why there isn't much strength to my sand. Consequently, Some parts of my mold couldn't be achieved. Anyway, On with the show!

So not exactly what I wanted, Now I have to drill the holes manually

I'll have to add more draft in my next print to make up for the weak sand. Also, I printed in PLA rather than ABS. The neat thing with ABS is you can acetone vapour polish it which gives it a very hard mirror shell and sand won't stick to it. You can get away with some vertical edges using that technique.

I might re-do my master and do another pour tomorrow. Then on with the more complicated manifolds!

Re: Custom Flange - 3d printing, CAD, Sand Casting

Posted: Fri Mar 25, 2016 4:54 pm

by TdracerTd

Will you be mass producing these? May be easier with a mill and some extruded flat bar if it's just a one off.

Re: Custom Flange - 3d printing, CAD, Sand Casting

Posted: Fri Mar 25, 2016 5:18 pm

by HQ355

Even plasma cutter and mill for small batch production

Re: Custom Flange - 3d printing, CAD, Sand Casting

Posted: Fri Mar 25, 2016 5:30 pm

by BennVenn

For something like this plate I agree, plasma, water or mill would be best. For manifolds with complex core geometry there is no better method than sand casting.

This simple adaptor was more to test the new sand before I get stuck into multi piece molds with cores.

And if I choose to do a production run, it is far more time and cost effective casting with a quick skimming on the mill/lathe.

Re: Custom Flange - 3d printing, CAD, Sand Casting

Posted: Fri Mar 25, 2016 6:16 pm

by TdracerTd

BennVenn wrote:For something like this plate I agree, plasma, water or mill would be best. For manifolds with complex core geometry there is no better method than sand casting.

This simple adaptor was more to test the new sand before I get stuck into multi piece molds with cores.

And if I choose to do a production run, it is far more time and cost effective casting with a quick skimming on the mill/lathe.

Don't get me wrong. Awesome project. I need to look into this sort of fab myself. I just meant that there may be easier methods for the project you are working on.